Inspired by the brilliant Ben Eater videos about building a 6502 computer, I’d thought I would have a go.

I have a bit of a soft spot for the 6502, having learned 6502 assembler on the Emma II 6502 trainer board when I was at college. The board is made by L.J Electronics Ltd. More info can be found here.

|

Emma II

|

Continuing with the the 6502 trainer board theme, I have an EPE 6502 Micro Lab. The Micro Lab was an Everyday Practical Electronics Magazine project for the Teach-In '93 magazine series during 1993. The Micro Lab hardware was designed by Keith Dye BEng (Tech) AMIEE and the Micro Lab Monitor software was written by Geoff MacDonald BSc (Hons) AMIEE.

|

Micro Lab

|

Micro Lab Technical Specifications

| Hardware |

|---|

| Microprocessor | 6502 8 bit |

| Clock speed | 1 MHz |

|

| Power | 5V DC |

| SRAM | 32KB with battery backup |

| EPROM | 32KB |

| Analogue Input | 0-2.5V accurate to 0.01V |

| Analogue Output | 0-2.5V accurate to 0.01V |

Displays

| 16 x 2 LCD with variable contrast

7 segment LED

8 data LEDs |

Keyboard

| 20 keys, interrupt driven

8 DIP switch data inputs

Reset switch |

I/O Ports

| 65C22 VIA providing:16 individually programmable I/O ports4 control linesserial outputhardware pulse counting |

Anyway I digress...

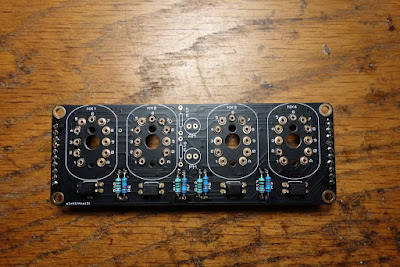

Clock Module

I built the clock module first, this is based on Ben Eater's clock but I only built the first part of his circuit. It uses the classic 555 timer configured in astable mode to provide the clock pulse. The clock is adjustable-speed (from less than 1Hz to a few hundred Hz). All computers require a clock pulse, this triggers the processor to perform each instruction.

The CPU

I'm using a modern version of the MOS 6502 which is made by WDC. The 6502 was used in many classic computers including the Atari 2600, Apple II, Nintendo Entertainment System, Commodore 64, Commodore VIC20 and the BBC Micro.

WDC’s updated W65C02S version of the legendary MOS 6502 has new opcodes and various improvements on the original. The “C” means CMOS, “S” static – unlike the dynamic original, registers are maintained without the need for a continuous clock. This means the CPU can be clocked extremely slowly or even stopped without any loss of data.

|

| W65C02 |

Connecting up the CPU

|

W65C02 pinout

|

- Pin 21 to ground and 5V to pin 8 will power the 6502.

- Pins 2, 4 and 6 are tied high through 3.3K pull-up resistors as does pin 38, Set Overflow(SOB) and pin 36, Bus Enable(BE)

To get things going the CPU requires a low signal on pin 40, reset. This simply means connecting the pin briefly to ground. A push button should do, although ideally the button would be properly debounced. I have built a debounce circuit based on a 74HC14 which debounces the reset button and gives a clean reset signal.

Finally the clock signal input on pin 37. With the data and address bus unconnected, it does absolutely nothing!